Rough diamonds often look like old pieces of glass to the untrained eye, and it is only once they have been cut and polished that they start to take on their beautiful appearance. Even the largest rough diamond ever found, known as the Cullinan Diamond looked unremarkable until it was cut into individual diamonds, some of which were used for the Crown Jewels.

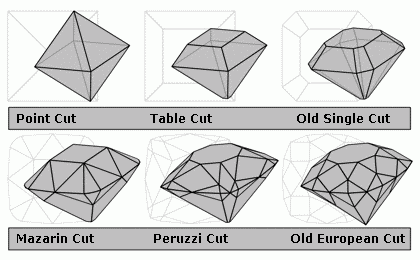

People have been cutting diamonds since the Middle Ages, and over time the patterns have evolved, producing increasingly attractive diamonds. By 1900 the old European cut was one of the most popular designs, and in many ways it resembles on paper what we think of as a modern diamond.

Around this time diamond cutting tools were improving, and there were new jewellery saws and lathes available to the diamond cutter. This meant that it was now possible to investigate whether there was a theoretically perfect cut of diamond, as inadequate tools were no longer the main limitation.

Evolution of diamond cutting prior to 1900

Finding the Perfect Cut

The young man who took up the challenge of looking for the perfect cut of diamond was Marcel Tolkowsky. He was well placed to investigate diamond cuts – not only did he belong to a family which had been cutting diamonds for generations, he was also studying for a PhD at the University of London in the School of Engineering. Tolkowsky’s PhD thesis focused on the grinding and polishing of diamonds and meant that he was able to use his knowledge of maths and science and apply it to the problem of finding the best possible cut for a diamond.

Brilliance and Fire

There are two main qualities which people are looking for in a diamond. The first is brilliance – this is a measure of how much light is reflected back to the person viewing the diamond. If light enters a diamond and simply leaves the back of the diamond, then it will appear dull and lifeless. The other quality is known as fire – this is the dispersion of white light into its constituent rainbow colours. The combination of brilliance and fire results in the sparkly effect which we all know and love.

Refraction

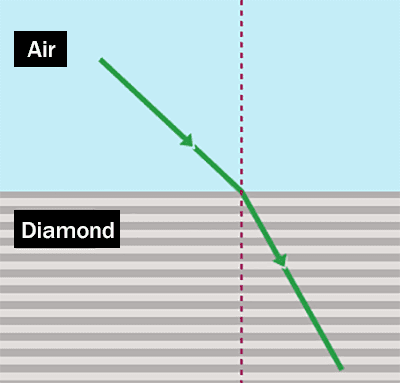

Marcel Tolkowsky looked at how individual light rays behave when they enter different cuts of diamonds. When light passes from air into a material like diamond it will change direction, in a process known as refraction.

The refractive index of a material can be calculated as follows:

Diamond has an extremely high refractive index of 2.42, in comparison with window glass which has a refractive index of 1.52. Diamond has one of the highest refractive indexes out of all naturally occurring materials, which is one of the reasons why it is so special.

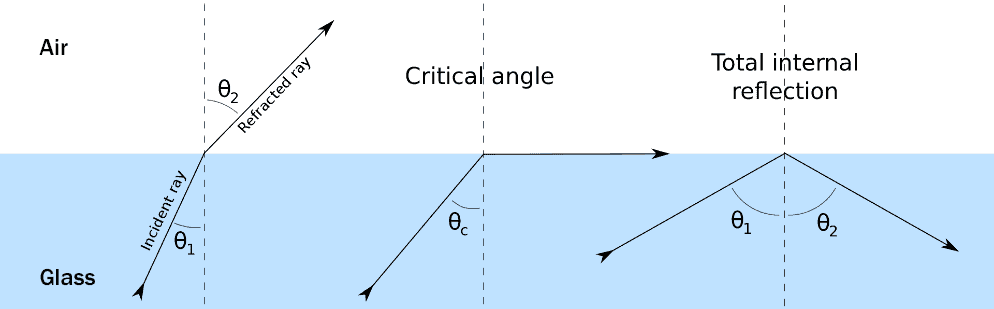

As you increase the angle of your light ray, it will eventually reach what is known as the critical angle. This means that the light will stop being refracted and instead it will be reflected. For diamond the critical angle is around 24 degrees, whereas with glass it is around 41 degrees.

An illustration of the critical angle when a light ray travels from glass to air

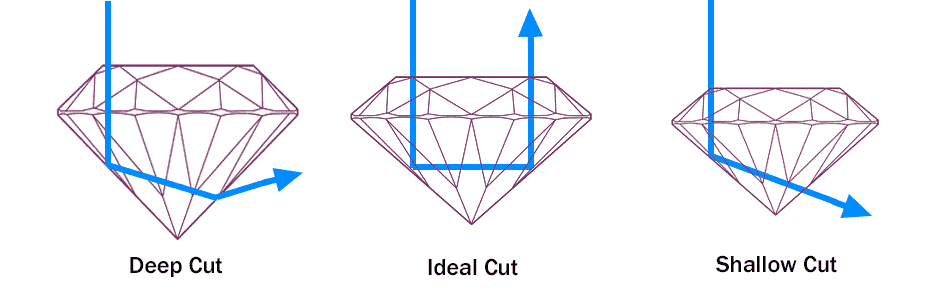

Tolkowsky used these facts to examine individual light rays. He wanted to design a diamond so that light would enter and strike the back face at an angle greater than the critical angle, initially creating internal reflection. He then wanted the light ray to hit the top face at an angle which was smaller than the critical angle so that it refracted out of the top of the diamond, reaching the eyes of anyone viewing the diamond. Tolkowsky found that some diamonds were cut too deep, whereas others were cut too shallow.

Arrow illustrates path of light through diamond

He used geometry to arrive at what is known as the ideal cut of diamond. This was designed to optimise both brilliance and fire, and many modern diamonds are based on Tolkowsky’s original design. A similar theory can be used to optimise the cut of other gem stones, using their respective critical angles.

Using Maths to Cut a Diamond

Diamond cutters also face the problem of making the most of their original stone and avoiding wastage. Experienced diamond cutters will expect to use only one third of a rough stone in order to produce their finished diamond, which is a huge waste given how expensive diamonds are. Mathematicians at the Fraunhofer Institute have been investigating how to improve on the judgement of an experienced cutter. They have used a mathematical technique known as “Semi-Infinite Optimisation” and their algorithms have led to an increase of around 10% in yield. This might not sound that much, but given the cost of diamonds, this is a significant improvement.

Article by Hazel Lewis